Example in Improving Soil Contamination and Environmental Counter-Measures

Covers everything from soil to water quality, including the linen that wraps your body.

Promising a green future with products that are kind to people and the earth.

01

A Motor Parts Manufacturing Company

- OILnax

- grease trap

- Manufacturing

- Industrial use

| Problem | Drain pipe in the factory dining hall was clogged and it was critical to correct the soared n-Hex value. |

|---|---|

| Solution | The value was corrected by applying OILnax to break down oil [fat] in grease trap in the factory. |

| Product used | OILnax for grease trap (Industrial use) |

-

Grease trap immediately after applying OILnax

-

Grease trap 10 hours after applying OILnax

02

IT device manufacturer

- OILnax

- grease trap

- Manufacturing

- Wastewater treatment

| Problem | Following the administrative recommendations measures, it was necessary to improve the n-Hex value of the drain water at the drainage processing gate. |

|---|---|

| Solution | Conducted breaking down of oil by continuous dripping of OILnax at the grease trap in the facility restaurant. |

| Product used | OILnax for grease trap |

03

Food processing manufacturer

- OILnax

- Soil contamination

- Manufacturing/Processing

- Wastewater treatment

| Problem | Fuel oil tank for a boiler cracked and nearly 1 ton of oil spilt out onto the premises. It was threatening to pollute the nearby farmland from the lower layer of soil within the facility grounds. |

|---|---|

| Solution | Applied OILnax for soil contamination. A digger was used where the contamination was severe. The soil was agitated [stirred] and flowed down to the lower layer of the ground. |

| Product used | OILnax for soil contamination |

-

OILnax for Soil contamination

04

Construction Company

- OILnax

- Soil contamination

- Ceramic manufacturing

- Oil pollution / Oil odor

| Problem | There was a problem of oil pollution and oil odour after attempting to improve the soil at the ruins of the dismantled boiler room at a ceramic manufacturing factory. The main concern was the complaints of oil odour by the neighbouring residents. |

|---|---|

| Solution | Applied OILnax for soil contamination. A digger was used where the contamination was severe. The oil odour was resolved by permeateing OILnax into the gound while the soil was being agitated. |

| Product used | OILnax for soil contamination |

05

Linen cleaning business

- OILnax

- Linen cleaning

- Restaurant

- Oil stain

| Problem | Cleaning service for uniform used by restaurants. They were having problems in removing various oil stains from the linen. They were struggling to balance between “removal of stains” using strong detergent and “durability of linen”. |

|---|---|

| Solution | Oil stains were removed. Fabric became long lasting due to OILnax being neutral detergent. |

| Product used | OILnax for cleaning (General use) |

-

Linen cleaning business

06

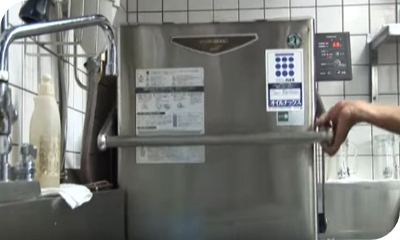

Restaurant chain (Restaurant specialized in pork cuisine)

- OILnax

- Restaurant

- Plumbing clog

- Dishwasher

| Problem | The drain pipes required to be cleaned several times a year in order to avoid drain blockage and to contain constant bad ordor caused by oil from pork fat. As the cost of pipe cleaning was high, they were seeking a solution that would also lower the cost. |

|---|---|

| Solution | Applied OILnax electrolysed alkaline type for dishwashers to the dishwasher. The client was happy as the number of regular pipe cleaning to address the bad ordor reduced, resulting in reduction in expenditure. |

| Product used | OILnax electrolysed alkaline type for dishwashers |

-

OILnax Application at Butakumi Restrant Group

*Please note: Some stores in the video are already closed. Plesae check the latest information.

Contact

Please feel free to ask us any questions or handling information regarding our products.